-40%

3,4,5 Axis Vertical Machining Center / Fully Enclosed ATC / CAD/CAM / CNC / CMM

$ 39597.36

- Description

- Size Guide

Description

www.directmotion.comFeatures & Benefits

|

Gallery

|

Demo

|

Build a Quote

|

Compare Models

|

Financing

DM VMC1277

3 to 5-Axis CNC Vertical Machining Center with built in CAD/CAM and CMM

32" x 20" x 20" Travels | 24 Tool ATC | 8K Spindle | 40 Taper

BASE PRICE: ,995

ON THE MACHINE PROGRAMMING:

CAD

Import step files or design 3D solid models on the machine.

CAM

Create toolpaths from CAD or import G codes on the machine.

CNC

Press 'cycle start' and the machine starts cutting.

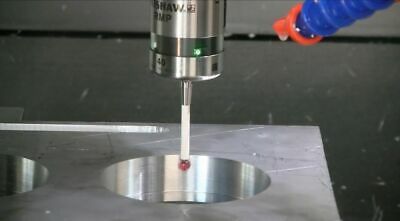

CMM

Set home, verify parts, or reverse engineer w/ probe.

THE DM ADVANTAGE IS 4C

An end-to-end design & manufacturing solution

The DM VMC Series are high-performance vertical machining centers powered by 4C - our PC-based software and control system. 4C seamlessly integrates 3D CAD/CAM/CNC and CMM in one easy-to-learn package - with no outside software. 3D solid model part programming is done right on the machine’s 40" 4K touch display. From prototype to production manufacturing, DM's VMC Series with 4C has you covered.

Cut a part on day one, bring work in house

If you can run Win10, you can run 4C. No G-code experience is required, and minimal CAD/CAM experience is needed. You'll be able to cut a simple part on day one of training regardless of your CNC experience level. 4C increases workflow efficiency because one person can often replace a conventional CAM programmer and CNC operator.

Learn 4C 5x faster, maximize production

Since 4C runs on the machine, changes to toolpaths are done on the shop floor. You won’t be walking back and forth between the machine and a CAM workstation (like conventional systems). This means program changes are nearly instant, and leads to learning 4C 5x faster than other CAM programs. You’ll also fine-tune your programs in less time, so you can spend more time making chips.

Internet-based support, no finger pointing

When you buy a DM machine, you’re getting an end-to-end solution. DM supports the entire system (electronics/software/mechanical). You’ll have one point of contact for everything, and can video call or instant message directly from your machine. Internet-based support streamlines remote diagnostics and communication. We can even remotely operate your machine, as if we were right there with you.

STANDARD EQUIPMENT

Software & Control:

4C CAD/CAM/CNC/CMM by Direct Motion

Operating System:

Windows 10

Interface:

40" 4K Touch Display

Fully Enclosed

with Sliding Doors

Tool Changer:

Arm Automatic Tool Changer (ATC)

Spindle:

8000 rpm, BT 40 Taper

Linear Rails:

XYZ axis

Chip Removal:

Chip Conveyor

Coolant Tank

Z Axis Pneumatic Counter Balance

Cooling:

A/C Unit for Control Cabinet

Pendant:

Remote Jog Handle

PC Hardware:

I5 Intel Processor, 8GB Ram, Solid State Drive (SSD), Mouse, Keyboard, Webcam, and Headset

Warranty:

1-Year Standard Warranty

**Please note: 4th/5th axis option in addition to the price listed here. See

optional equipment

pricing on our website.